The Evolution of Manufacturing

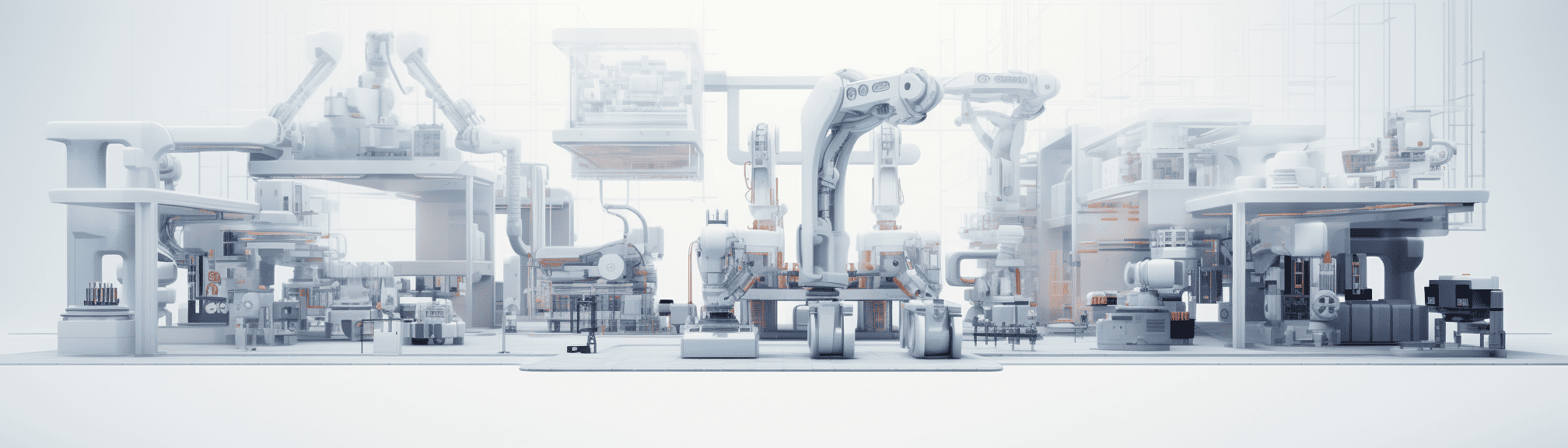

Manufacturing has always been the backbone of economies worldwide. The sector has witnessed significant shifts from the early days of manual labour and rudimentary tools to the sophisticated machinery of the Industrial Revolution. Today, as we navigate the complexities of the 21st century, manufacturing is undergoing yet another profound change, driven by digital technologies.

In the past, manufacturers relied heavily on physical labour and tangible assets. However, with the advent of digital technologies, there’s been a shift towards data-driven processes and automation.

This transformation isn’t just about integrating new technologies; it’s about reimagining the entire manufacturing process.

Forbes highlights several trends shaping this transformation, from AI to collaborative robots.

The Role of IT in Modern Manufacturing

Information Technology (IT) has emerged as a pivotal player in this transformation. Modern manufacturing units are no longer isolated entities but interconnected hubs that leverage data for enhanced decision-making. IT improvements have:

- Streamlined operations by integrating various functions, from procurement to distribution.

- Enhanced real-time monitoring, allowing for quicker responses to any discrepancies.

- Facilitated better communication between different departments, leading to more cohesive strategies.

Moreover, with the rise of cloud computing and advanced analytics, manufacturers can now access previously out-of-reach insights. This has led to more informed decision-making and a proactive approach to challenges.

The Shift to Digital

Manufacturers today recognise the immense potential of going digital. It’s not just about staying competitive; it’s about future-proofing businesses. Adopting a digital-first approach has several benefits:

- Efficiency: Automated processes mean fewer errors and faster production cycles.

- Cost Savings: Digital operations often translate to reduced overheads and operational costs.

- Scalability: Digital platforms can easily adapt to increasing demands, ensuring businesses are always ready for growth.

The Digital Tools Reshaping Manufacturing

Advanced tools and technologies underpin manufacturing’s digital transformation. These innovations are not just enhancing existing processes but are paving the way for entirely new production and management methods

Artificial Intelligence (AI) and Machine Learning (ML): AI and ML are at the forefront of manufacturing’s digital revolution. These technologies enable predictive maintenance, where machines can forecast when they’ll need repairs. This not only reduces downtime but also extends the lifespan of the equipment.

Internet of Things (IoT): IoT devices collect vast amounts of data from the factory floor. This data, when analysed, provides insights that can lead to more efficient operations. For instance, sensors can monitor temperature, humidity, and other conditions to ensure optimal environments for specific manufacturing processes.

The Human Element in Digital Transformation

While technology plays a pivotal role, the human element cannot be overlooked. Employees need to be trained to work alongside these new digital tools. This involves:

- Upskilling: Ensuring the workforce has the necessary skills to operate new digital tools.

- Change Management: Helping employees navigate the changes brought about by digital transformation.

- Collaborative Workspaces: Creating environments where humans and machines can work in tandem, maximising the strengths.

Furthermore, a culture that promotes continuous learning and adaptation is crucial. This ensures that as technology evolves, the workforce can keep pace, ensuring that the benefits of digital transformation are fully realised.

Challenges and Considerations

Embracing digital transformation is not without its challenges. Manufacturers need to consider:

- Cybersecurity: As operations become more interconnected, they also become more vulnerable to cyber threats. Robust security measures are essential.

- Integration with Legacy Systems: Not all existing systems will be compatible with new digital tools. Finding ways to integrate them can be complex.

- Cost Implications: While digital tools can lead to long-term savings, the initial investment can be significant.

The Future of Manufacturing

The digital transformation of manufacturing is not just a fleeting trend; it’s the future. As technology continues to evolve, so will the methods and strategies employed in manufacturing.

This evolution will further solidify the role of digital tools in the sector.

Sustainability and Eco-friendly Manufacturing: With increasing global emphasis on sustainability, digital tools offer solutions to make manufacturing more eco-friendly. Advanced analytics can help in waste reduction, while AI can optimise energy consumption.

Customisation and Personalisation: Digital tools allow for greater customisation in manufacturing. 3D printing, for instance, can create bespoke products tailored to individual preferences.

Global Collaboration: Digital transformation facilitates collaboration across borders. Cloud computing and advanced communication tools mean that teams from around the world can work together seamlessly.

In essence, the digital transformation in manufacturing sets the stage for a more efficient, sustainable, and customised future. Manufacturers that embrace this change will undoubtedly be at the forefront of the industry.

How We Can Help

At EfficiencyAI, we combine our business analysis skills with technical expertise with a deep understanding of business operations to deliver strategic digital transformation consultancy services in the UK that drive efficiency, innovation, and growth.

Let us be your trusted partner in navigating the complexities of the digital landscape and unlocking the full potential of technology for your organisation.